1 - DESIGN BRIEF

2 - AERODYNAMIC DEVELOPMENT: BICYCLE AND CYCLIST, ONE SINGLE ENTITY

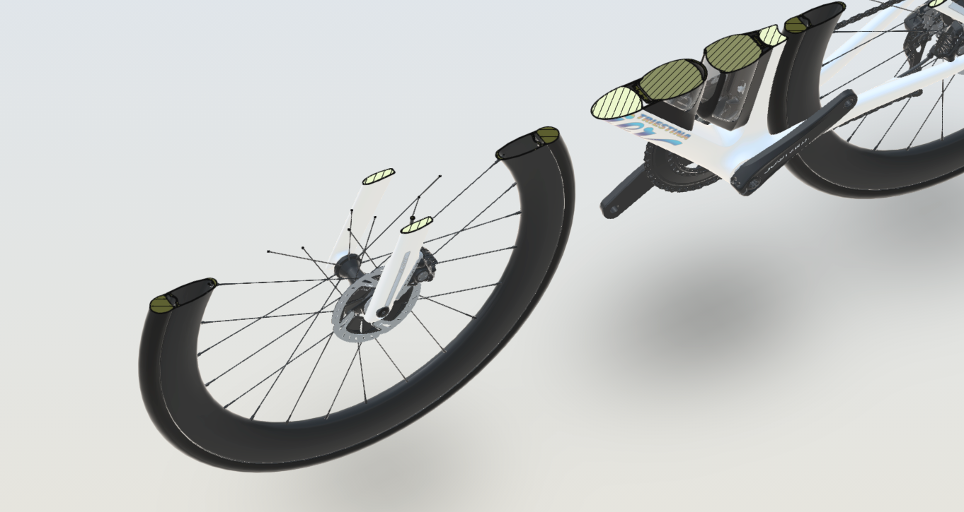

3 - MORE DATA, LESS DRAG: THE NEW AERODYNAMICS OF THE FORK

4 - THE HEAD TUBE: SLIM, CLEAN, FAST

5 - NEW F-BAR ID2 HANDLEBAR

6 - DOWN TUBE AND AEROKIT, THE MOST COMPLEX CHALLENGE

7 - AERODYNAMIC SEATPOST AND NEW SHIMANO DI2 BATTERY HOUSING

8 - REAR SEATSTAYS: A SILENT REVOLUTION

9 - POWERMETER MAGNET HOUSING: AERODYNAMICS IN EVERY DETAIL

10 - THE VERDICT FROM THE SILVERSTONE WIND TUNNEL: MEASURABLE PERFORMANCE, REAL ADVANTAGES

11 - AERODYNAMICS AND LIGHT WEIGHT, THE KEY TO PERFORMANCE

12 - GEOMETRIES DEVELOPED DIRECTLY WITH PROFESSIONALS

13 - THE CULTURE OF SPEED, WILIER TRIESTINA'S CREED

1 - DESIGN BRIEF

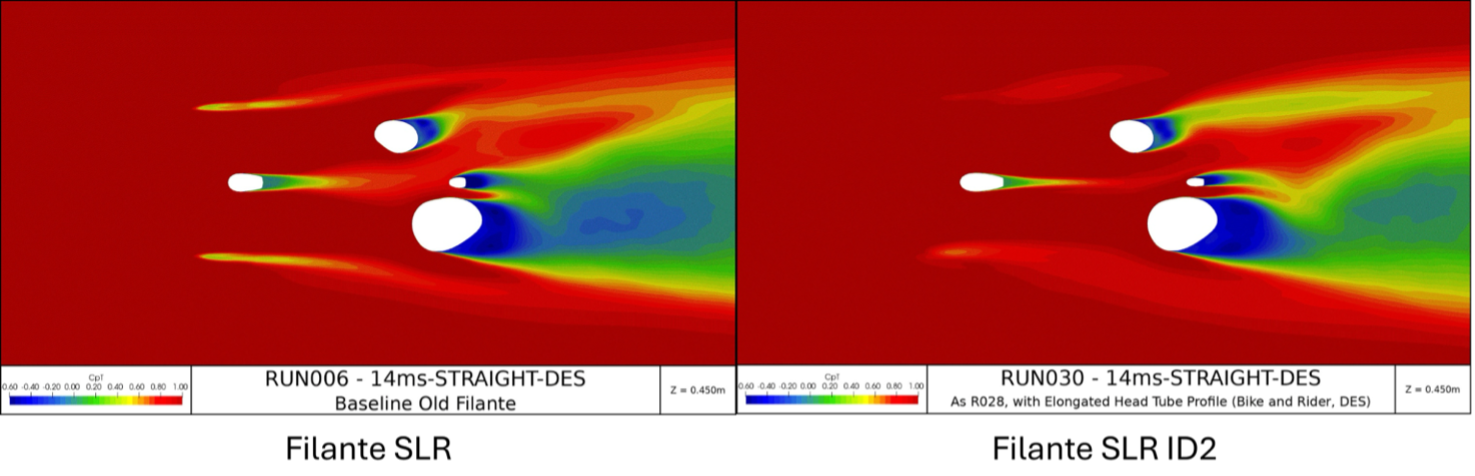

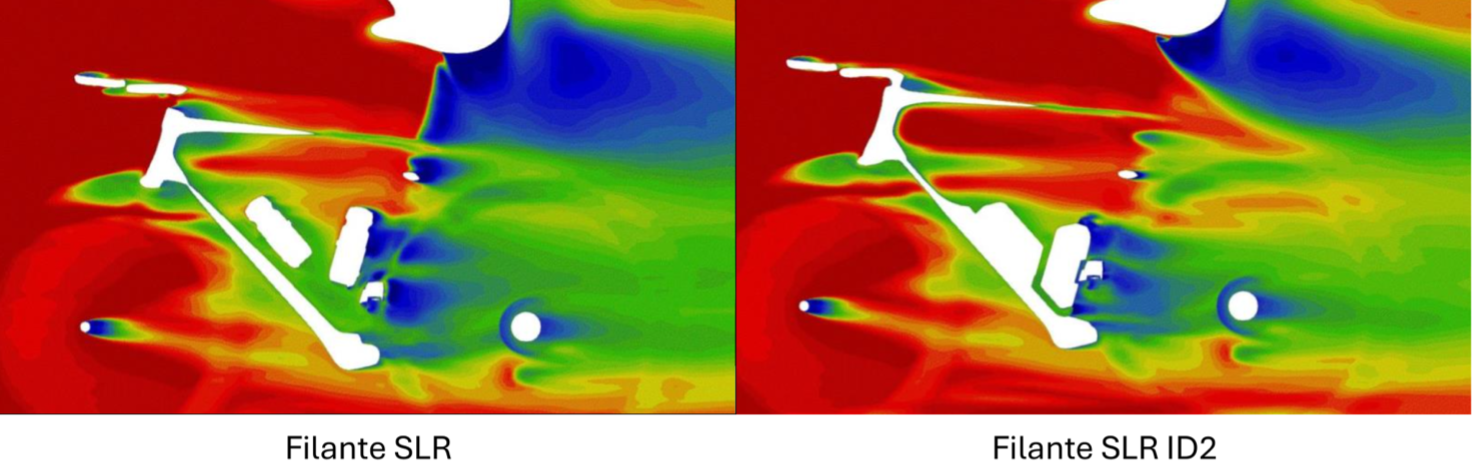

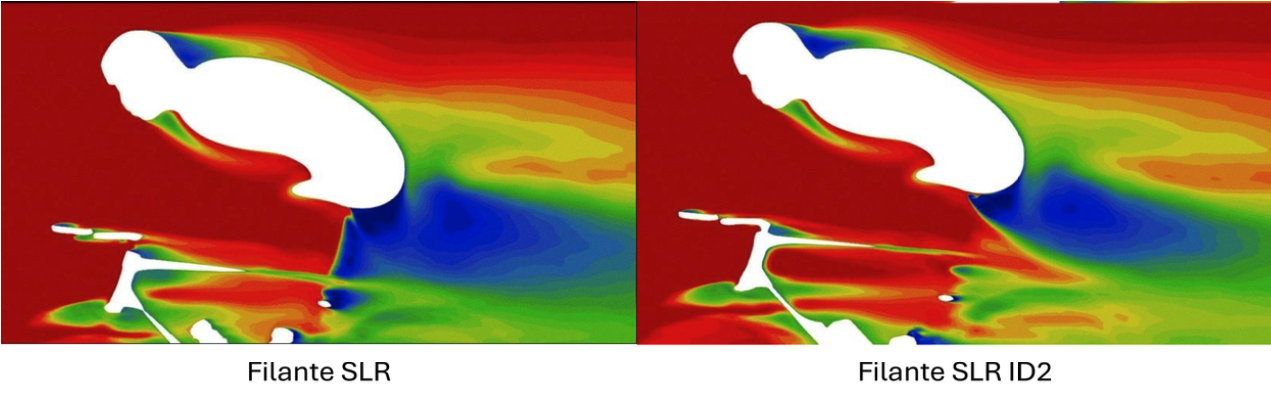

2 - AERODYNAMIC DEVELOPMENT: BICYCLE AND CYCLIST, ONE SINGLE ENTITY

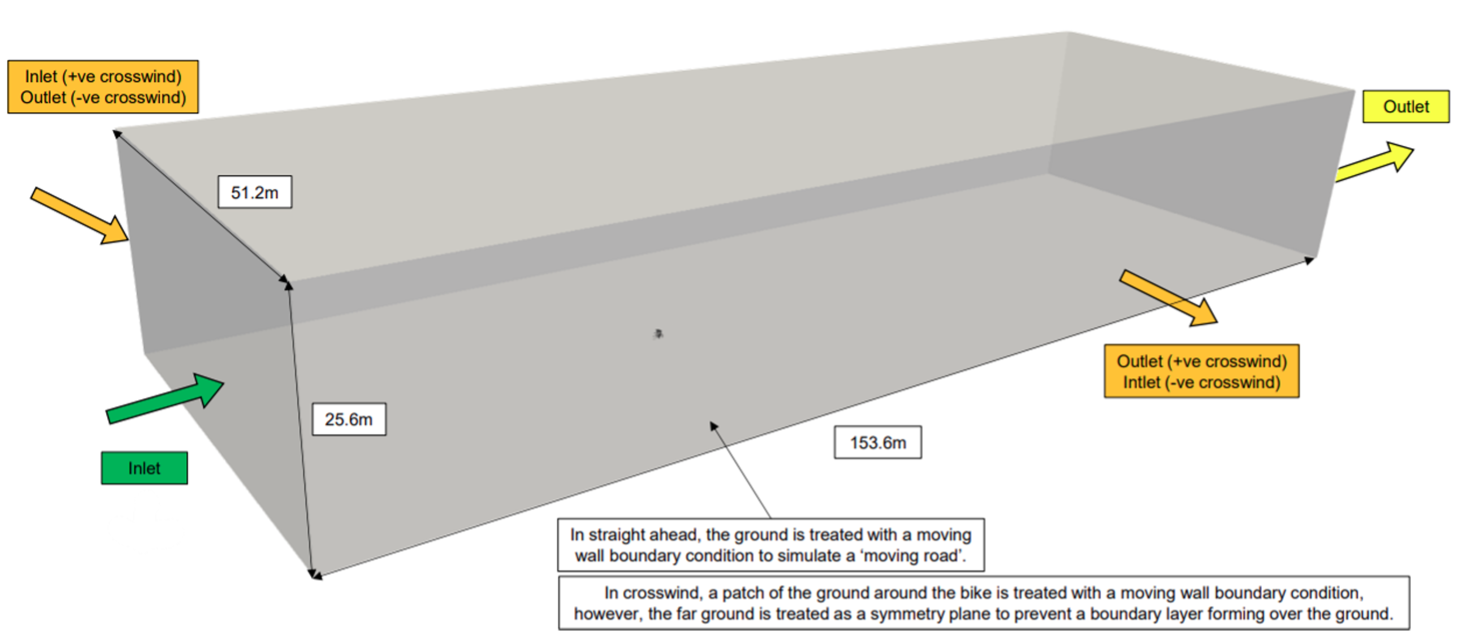

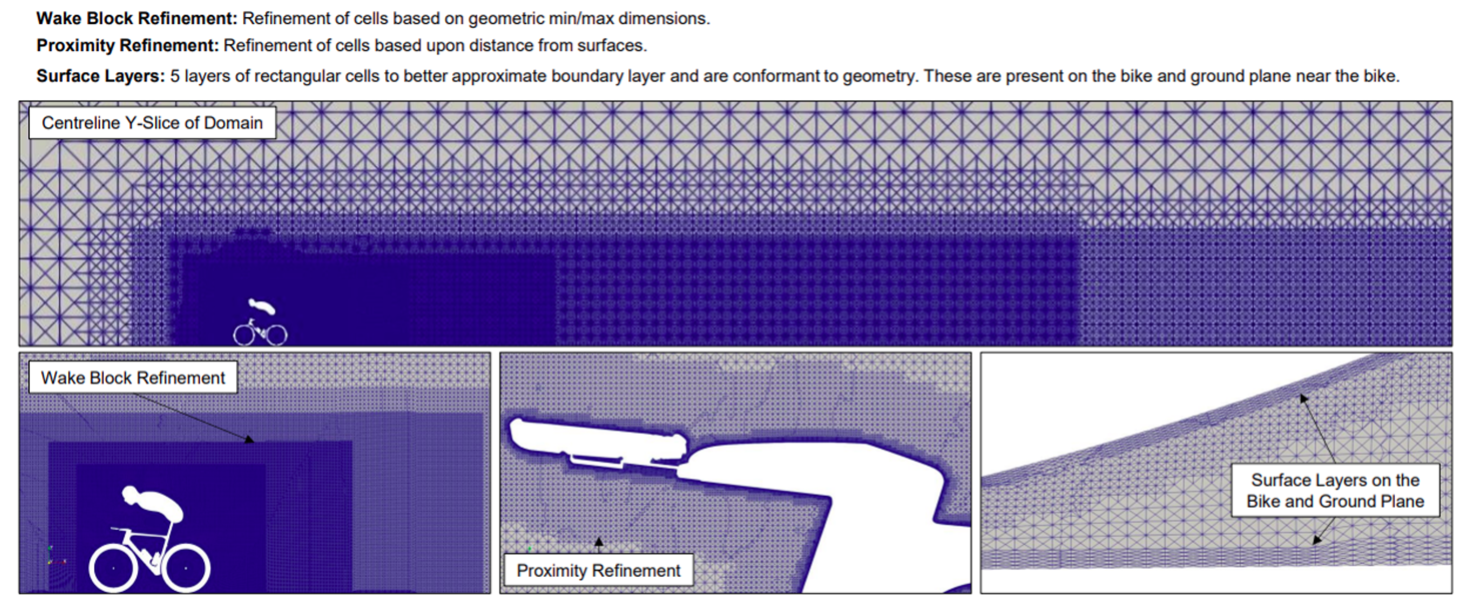

All this helped to complete a first analysis of the design idea using CFD software. By solving the Navier-Stokes equations, this software simulates virtually and describes the behaviour of a fluid (air in our case) around an object. Once the object has been defined, the first step is to define the physical and environmental conditions under which it will be analysed.

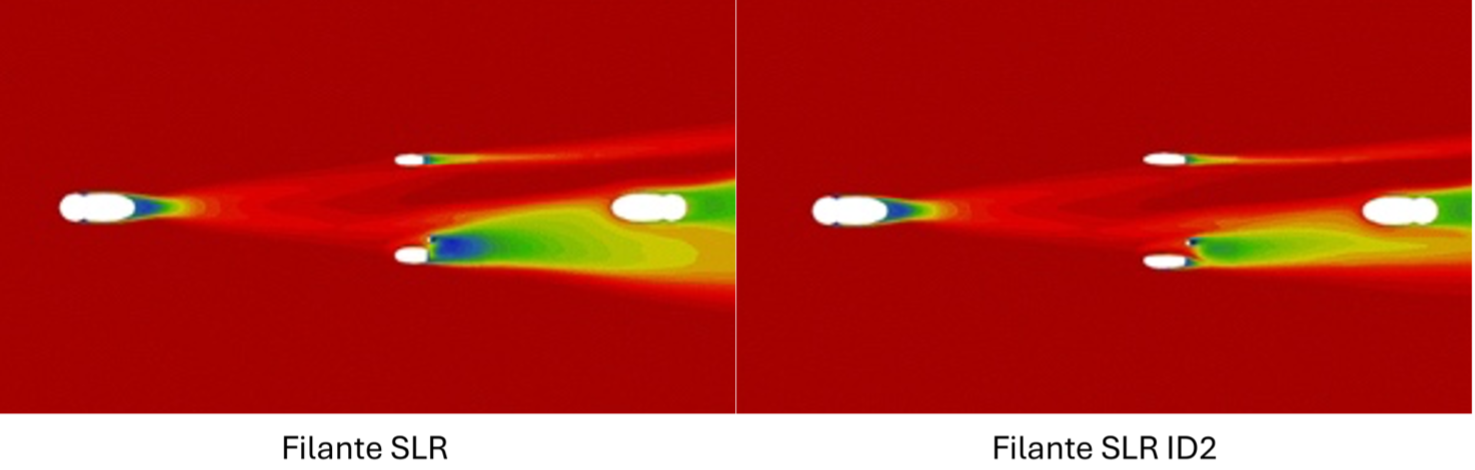

3 - MORE DATA, LESS DRAG: THE NEW AERODYNAMICS OF THE FORK

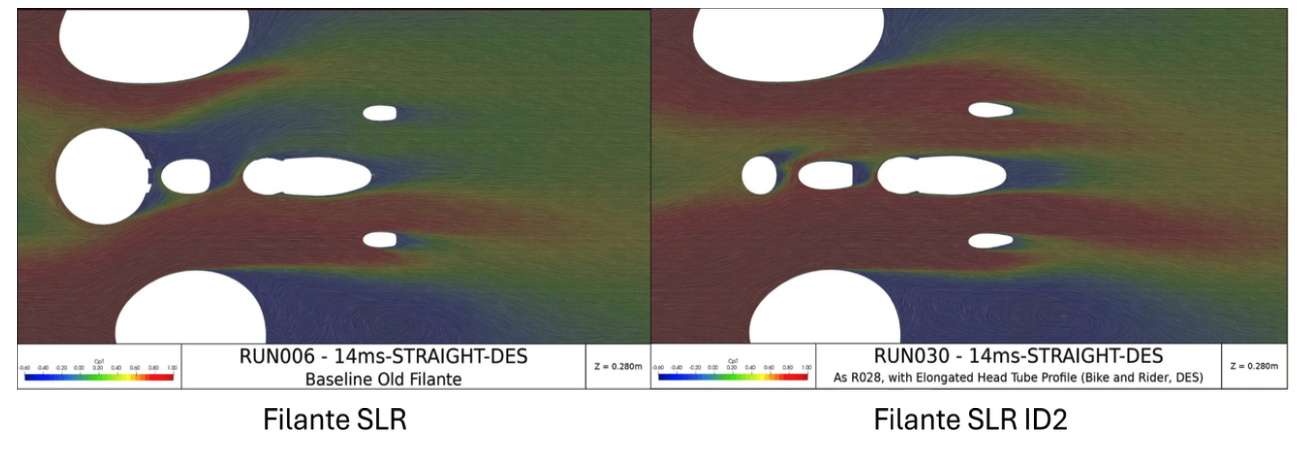

4 - THE HEAD TUBE: SLIM, CLEAN, FAST

5 - NEW F-BAR ID2 HANDLEBAR

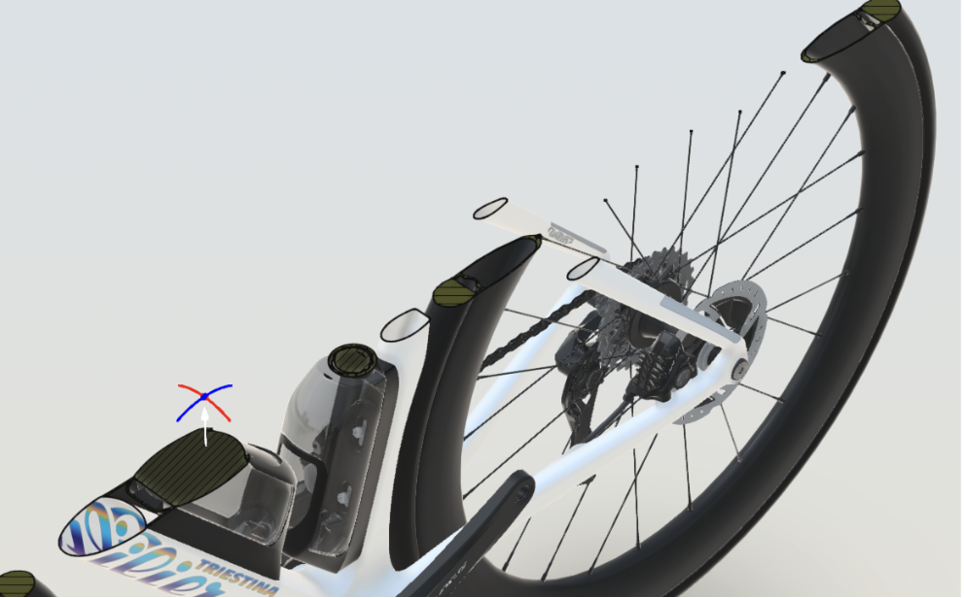

6 - DOWN TUBE AND AEROKIT, THE MOST COMPLEX CHALLENGE

7 - AERODYNAMIC SEATPOST AND NEW SHIMANO DI2 BATTERY HOUSING

8 - REAR SEATSTAYS: A SILENT REVOLUTION

9 - POWERMETER MAGNET HOUSING: AERODYNAMICS IN EVERY DETAIL

10 - THE VERDICT FROM THE SILVERSTONE WIND TUNNEL: MEASURABLE PERFORMANCE, REAL ADVANTAGES

11 - AERODYNAMICS AND LIGHT WEIGHT, THE KEY TO PERFORMANCE

12 - GEOMETRIES DEVELOPED DIRECTLY WITH PROFESSIONALS

- The rear triangle has been slightly lengthened: a choice that allows for better integration of the new transmission groupsets with the UDH dropout, increases tyre clearance (up to 34 mm), and improves the overall stability of the bicycle.

- The Reach & Stack graph is less steep and more “stretched”, expanding the fitting coverage and particularly improving the small and large sizes.

- New handlebar bend design, with geometries also dedicated to the Asian market.

- XS > 75 - 35/38

- S > 90 - 37/40

- M > 100 - 37/40

- L > 110 - 37/40

- XL > 110 - 39/42

- XXL > 120 - 39/42

13 - THE CULTURE OF SPEED, WILIER TRIESTINA'S CREED